TREPEND

Redefining Manufacturing with

Innovation and Service Excellence

1

Manufacturing

SIM BIZ

A Trendsetter in Manufacturing as a Service (MaaS)

Your One-Stop Solution for Cutting-Edge, Scalable, and Cost-Effective Manufacturing!

2

Welding

AIM

Application In Manufacturing

- Welding Consumables

- Welding Machine

- Machine Tools

TRUSTED BY TEAMS FROM TOP BRANDS

What Sets Us Apart

Expertise and Experience

Being in Manufacturing Industry since 2008, our team comprises seasoned professionals who bring a wealth of knowledge and expertise to every project. From rapid prototyping to full-scale production runs, we have the capabilities and insights to guide our clients through every stage of the manufacturing process. We have expertise in Fabrication involving critical and difficult to weld material, Machining capabilities include Smallest of operation involving micro tools to those with machining size which are few meters in size, Powder metallurgy, Painting, Castings, Forgings.

Technology-Driven Solutions

We leverage the latest advancements in manufacturing technology, including advanced robotics, additive manufacturing (3D printing), CNC machining, Robotic welding and more. Our commitment to innovation ensures that we stay ahead of industry trends and deliver superior quality products with precision and efficiency.

Flexible and Scalable Operations

Whether you require small-batch production or large-scale manufacturing, our flexible production facilities can accommodate varying demands seamlessly. Our scalable operations enable businesses to adjust production volumes quickly in response to market fluctuations, minimizing lead times and optimizing cost-efficiency.

Customer-Centric Approach

At Trepend Sim Biz, we prioritize customer satisfaction above all else. We work closely with our customers to understand their unique requirements, offering personalized solutions that align with their goals and objectives. Our dedication to service excellence is reflected in every aspect of our operations, from initial consultation to final delivery.

Get Started With Trepend Sim Biz

Whether you are a startup looking to bring a new product to market or an established enterprise seeking to optimize your manufacturing operations, Trepend Sim Biz is here to support you every step of the way. Contact us today to learn more about how our Manufacturing as a Service (MaaS) can benefit your business.

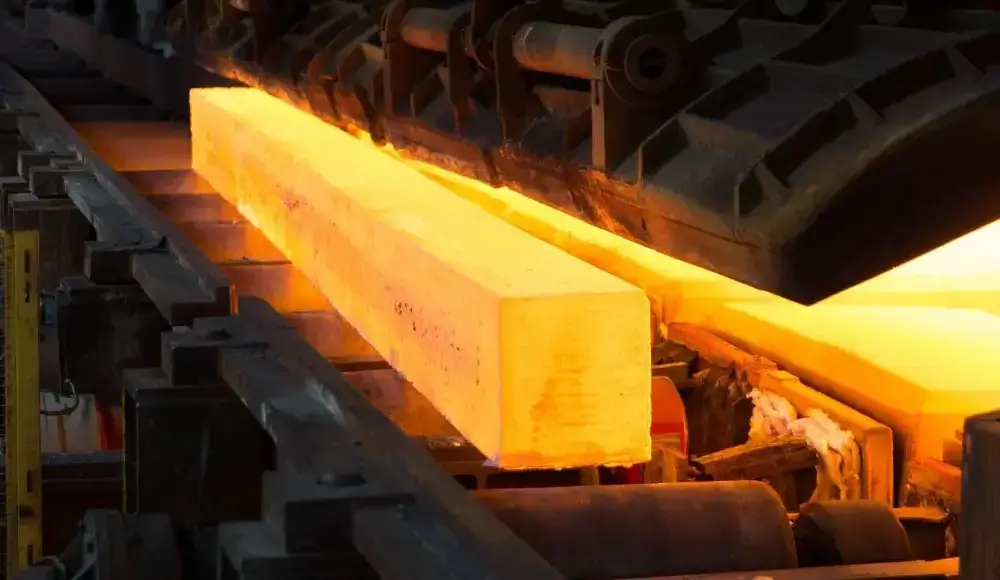

Forging

CNC Machining

Casting

Heavy Engineering

Sheet Metal

Injection Molding

Get quotes, lead times, and feedback instantly. Just fill out our simple form, and we will handle the rest.

Looking for a new product development?

Service

Info

File

Supoorted File Type: PDF | JPG | JPEG | PNG | STEP | STP | SLDPRT | STL

Services We Offer

Rapid Prototyping

Turn your ideas into tangible prototypes quickly and cost-effectively.

Low-Volume Production

Produce small batches of products without compromising on quality or efficiency.

Custom Manufacturing

Tailor-made solutions to meet specific design and production requirements.

Supply Chain Integration

Seamless integration with your supply chain to streamline logistics and ensure timely delivery.

SIM BIZ

Become a Manufacturing Partner

We being "Manufacturing Aggregator" and one stop solution for all the cutting-edge technology with unparalleled service to deliver flexible, scalable, and cost-effective manufacturing solutions tailored to meet the diverse needs of our clients.

AIM

Application In Manufacturing

TrepenD AIM is a team of experienced professionals having strong experience in Welding Consumables, Welding Machines and Machining tools; hailing from core manufacturing experience carried from topmost Indian and global engineering giants.

Learn More

TREPEND

Advantages With Sim Biz

At Trepend, we offer comprehensive local market knowledge and a global network of approved suppliers. Our flexible, data-driven approach ensures cost-effective, timely delivery tailored to your unique requirements.

Delivering Detailed Solutions

Each project includes detailed material specifications, finish quality, and dimensions, along with comprehensive technical documents, such as 3D models and engineering drawings.

Flexible Pricing

Each project includes a payment for our partners. Test orders have a fixed price, while real orders allow partners to propose their own price if the initial offer isn't suitable.

Technical Documentation

Each project comes with technical documents, including 3D/2D models and drawings. Partners can download these documents to evaluate their capability to produce the required item.

Material and Manufacturing Technology

Each project clearly states the required material type and the necessary manufacturing technology for production.

Defined Delivery Terms

Each project specifies clear delivery terms, shipping method, timeframe, and exact production and dispatch deadlines.

Terms and Conditions

Our terms and conditions are transparent, providing partners with a comprehensive understanding of all aspects related to pricing, production, and delivery.

Large Scale Manufacturing ?

Certified and Quality Driven Manufacturing Consulting

Securely upload your project files or contact us to schedule a call with our experienced consultants.

Manufacturing Capacity

Casting

Forging

Machining

Injection Molding

Fabrication

Ferous Casting

Mold size(max): 1m X 1m

Weight Range: 1 KG ~ 30 KGS

Mold size(max): 1.5m X 1.5m

Weight Range: 30 KG ~ 150 KGS

Mold size(max): 3m X 3m

Weight Range: 100 KG ~ 1000 KGS

Mold size(max): 500 MM X 500 MM

Weight Range: 0.250 KG ~ 20 KGS

Mold size(max): 500 MM X 500 MM

Weight Range: 0.100 KG X 20 KGS

Non-Ferous Casting

Capacity: 5000 MT/a

Range of weight: 100 gm to 20 KGS

Mold size(max): 1 M X 1 M

Weight Range: 0.5 KG X 50 KGS

Mold size(max): 1 M X 1 M

Weight Range: 0.5 KG X 50 KGS

Forging

Capacity: 20,000 Tons per Annum

Hammering: 5 Ton

Range of weight: 0.2 KG to 200 KGS

Hammering: 1600 Ton Hydraulic press

Ring size: 350 MM OD to 3000 MM OD

Range of weight: 15 KGS to 3200 KGS

Material

Machining

1 to 1000 MM

1 to 1000 MM

Material

Plastic

1250 X 1250 MM

Hammering: 1600 Ton Hydraulic press

Material

Heavy Fabrication

24000 MT/a

Sheet Metal Fabrication

0.8 to 25mm

Material

Why Sim Biz

100+

Active Clients

5000+

Parts Manufactured

15+

Manufacturing Process

100+

Material Processed

100+

Machines

50+

Manufacturing Partners

How We Work

Our customers love our service

Testimonials

Don't just take our word for it, read from our extensive list of case studies and customer testimonials.

Working with Trepend Sim Biz has been a game-changer for our company. Their expertise in additive manufacturing has allowed us to push the boundaries of what we thought was possible. The precision and quality of the products they deliver are unmatched.

Jane Cooper - CEO SomeCompany

The team at Trepend Sim Biz brings a wealth of knowledge and experience to every project. Their customer-centric approach ensures that our unique requirements are always met. We've been consistently impressed by their dedication to innovation and quality, making them a reliable partner for our manufacturing needs."

John Doe - CEO SomeCompany

As a startup, we needed a manufacturing partner that could grow with us. Trepend Sim Biz's flexible and scalable operations have been instrumental in our success. They have supported us from rapid prototyping to full-scale production, always delivering on time and within budget.

John Smith - CEO SomeCompany