TREPEND

CNC Machining Services

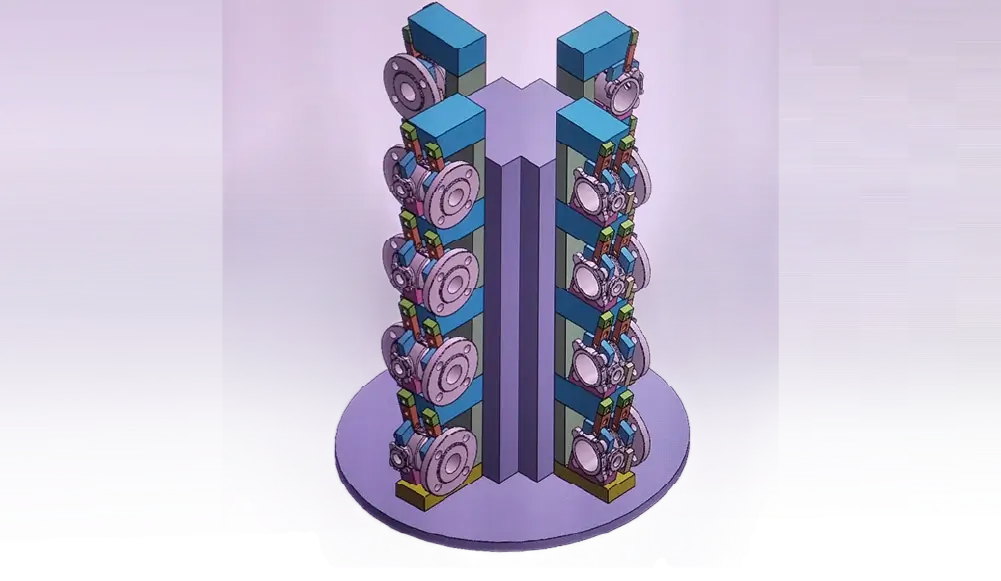

Sim Biz specializes in fabrication and structural engineering for industries like chemical plants, power plants, and reactors. Using the latest technology and engineering principles, we solve complex industrial challenges with a focus on precision, safety, and efficiency.

Our CNC Machining Offerings

At SIM BIZ, our CNC machining services provide precision, efficiency, and reliability for a wide range of industrial applications. By Using CNC technology, we offer superior machining solutions tailored to meet the exact specifications of our clients.

VMC Machining

CNC Turning

Advanced Work Holding

CAD / CAM Service

CNC Wire Cut

Request Your Consultation Today

Expert Solutions

Timely Project Completion

Competitive Pricing

Looking for a new product development?

Service

Info

File

Supoorted File Type: PDF | JPG | JPEG | PNG | STEP | STP | SLDPRT | STL

Processing...